sheet metal bending guidelines Guidelines for Sheet Metal Fabrication Design. As stated before, the design for sheet metal fabrication needs attention to some design requirements. Most of those requirements depend on the overall design of the product. For instance, a simple product would not have many requirements but an intricate geometry would naturally need more processes . Check out our metal stars selection for the very best in unique or custom, handmade pieces from our home decor shops.

0 · sheet metal guidelines pdf

1 · sheet metal calculations pdf

2 · sheet metal bending guide pdf

3 · sheet metal bending chart

4 · sheet metal bending basics

5 · sheet metal basic design guidelines

6 · homemade sheet metal bender plans

7 · basics of sheet metal design

TMS Titanium is a supplier and stocking distributor of titanium mill products. We stock the highest quality products, including sheet, plate, block, bar, fasteners, tubing, pipe, billet, ingot, forgings and more.

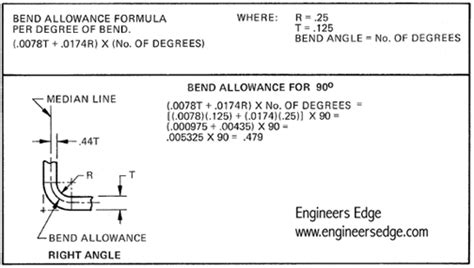

sheet metal guidelines pdf

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .Before submitting your sheet metal bending request, it is important to review our guidelines. Check them out now. . Guidelines for bending. Table of content. General; Tolerances; Internal radius; Minimum leg length; Maximum bending .In sheet metal bending, the K-factor is a crucial parameter that determines the amount of material elongation and deformation during the bending process. It is a constant value used to calculate the bend allowance, which helps determine the final dimensions of the flat sheet before bending.

Sheet Metal Bending and Forming Guidelines. We suggest the following design rules to bend the metal parts within our tolerance range of precisely ± 0.25 mm in length and ±1 °. K-factor. It is the ratio of the distance .

Guidelines for Sheet Metal Fabrication Design. As stated before, the design for sheet metal fabrication needs attention to some design requirements. Most of those requirements depend on the overall design of the product. For instance, a simple product would not have many requirements but an intricate geometry would naturally need more processes .

How Metal Bending Works. Ordering Bent Parts from OSH Cut. Bending Terminology. Bending Design Rules. Brake Tooling . Selecting Powder Colors. Powder Coating Design Rules. Sheet Metal Bending Guidelines. CONTACT. OSH Cut, Inc. 3052 North 170 East, Unit 1 Spanish Fork, UT 84660. Hours: 8 AM to 4 PM, M-F. Closed weekends. Phone: 801-850-7584 . Techniques of Sheet Metal Bending . Aspects Influencing the Selection of a Bending Method. When it comes to sheet metal bending, the choice of method can significantly influence the final product’s quality and appropriateness for its intended application.Factors such as the material’s malleability, thickness, and the desired bend angle and radius are crucial . In air bending, the punch pushes the sheet metal into the depression of the die but never to the point where the sheet metal actually comes in contact with the die. The controlled application of force will inevitably result in a lot of springback.

Sheet Metal Bending. Sheet metal bending is a forming technique that makes V, U or channel shapes by deforming metal around a straight axis. . Different international guidelines standards are set for sheet metal tolerances. These guidelines and standards guarantee quality and consistency across different manufacturers and industries. ISO 2768.

Here you can specify many of the sheet metal specific properties including bend radius, K-factor, and bend relief dimensions. These can be fixed values or formulas based on the material thickness. (Note: you can find all of this information for your chosen material and thickness in our bending calculator as well.) Figure 1-18 Z-shaped step bending. VI. Bending by Press Brake Machine. There are two categories of bending machines: ordinary bending machines and CNC bending machines. CNC bending machines are typically used for sheet metal bending in communication devices due to the need for high precision and the irregular shape of the bend.. The basic principle of the .

There are various sheet bending methods: V-bending: This is where the bending tool provides the force needed to bend the metal material (placed on top of the V-die) at the desired angles. This technique can bend steel plates with no change in their positions. Roll bending: This technique bends steel sheets into curved forms or rolls.It employs the press . Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments. The bending process is most common in sheet metal fabrication. In this process, sheet metal is bent at the desired angle to form the final shape. It uses the Press Braking Machine made up of two parts, a punch and a die. The workpiece is placed between these two parts. The force applied by the punch and depth of the die decides the bending angle. Specific tolerance guidelines integral to sheet metal fabrication are detailed in the table below. Each entry details the acceptable variance for various methods of fabrication and assembly. With values expressed in both millimeters and inches, the table serves as a reference, covering aspects from forming and bending to the relationships .

What is Sheet Metal Fabrication? Sheet metal fabrication is a highly versatile process used in the manufacturing industry to create various parts and components. This process involves cutting, forming, and assembling . Here are some key safety guidelines for sheet metal bending operations: Machine guarding: Enclose or barricade pinch points around the press brake dies to prevent accidental hand contact. Safety blocks: Insert .

sheet metal calculations pdf

Sheet metal drawings serve as the foundation for sheet metal engineers to conduct sheet metal fabrication, aiding them in accurately understanding the structure and requirements of the part, thus enabling . Sheet Metal fabrication is the building of metal structures by cutting, bending, and assembling processes. It is a value added process that involves the . Design Guidelines Tolerance No machine can hold dimensions precisely to the nominal value, so there must be acceptable degrees of variation. If a part is manufactured, but has dimensions . Another important consideration when designing sheet metal parts is bend orientation. Bends originating from the same plane should be oriented in the same direction to avoid the need of reorienting the part. This will save both money and time. Keeping a consistent bend radius across all bends will also make designs more cost-effective because .The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part stretches. . Bending Deformation Guidelines. Hardware Catalog. Drill Size Reference Chart. Bending .

Types of Sheet Metal Rolling Machines. Sheet metal rolling machines come in various types to suit different applications. 1. Three-Roller Bending Rolls: These machines employ three rolls to bend metal sheets, offering precise control and versatility. 2. Four-Roller Bending Rolls: Incorporating an additional support roll, these machines provide .

material thickness from edge of cutout to bend radius tangency. • L esser spacing requires secondary operations aft er bending and adds to manufacturing costs. • Form angle and form radii should be made as large as possible. • Offset should be minimized. [email protected] | 607.227.7070 | www.incodema.com • Strengthens bends locally. Sheet Metal Bend Radius: Guidelines for Proper Bending Understanding the Importance of Sheet Metal Bend Radius. When it comes to sheet metal fabrication, the bend radius plays a crucial role in determining the success and quality of the final product. The bend radius refers to the minimum radius that a sheet metal can be bent without causing .7 Must-Follow Sheet Metal Design Guidelines. Based on some standard design for manufacturing practices, thorough analysis of results and changing industrial requirements, following are the design guidelines that you should be following to improve your sheet metal design. . Minimum Sheet Metal Bending Radius. This is controlled by the tool and . *This article was updated on February 27, 2023. Our CNC bending service here at SendCutSend is affordable and accessible, making sheet metal bending available to everyone. There are a few guidelines you’ll need to follow to make sure that your bent sheet metal part is viable and successful.Watch the video and follow along with the guide below to help plan .

Download this article in PDF format. In sheet-metal fabrication, parts are formed from metal sheets by punching, cutting, stamping, and bending. 3D CAD files are created using a host of different .View guidelines and best practices for all of SendCutSend's services, including laser cutting, waterjet cutting, bending, CNC routing, tapping & powder coating. . Guide to Solidworks Sheet Metal Bending Read More » VIEW MORE TUTORIALS. Additional charts and guidelines. Min/Max Part Sizes. Processing Min/Max Part Sizes. Part Density Guidelines.

What is running through your neighborhood is a thick underground cable containing perhaps 25 or 50 pairs of copper wires. The little green box is a place where the 50-pair cable pops out of the ground so that a phone company employee can splice into it.

sheet metal bending guidelines|homemade sheet metal bender plans